Industrial tanning

Tanning is – depending on how you do it – the art, craft or industrial process of turning the raw animal hide into a conserved product called leather.

The standard tanning process is basically as follows. 1. Raw hides are unhaired using a lime solution and then unnecessary flesh is removed with a machine. 2. Hides are tanned in liquids containing mineral, synthetic or vegetable tanning agents. 3. Hides are split and shaved into a desired thickness. 4. Hides are fattened and normally dyed in new liquids. 5. Liquid is pressed out of hides and they are dried in hot air or vacuum. 6. Hides are finished by painting, printing or imprinting.

Traditional tanning is known as a truly dirty process. It has involved the use of human and animal excrement and animal brain. It used to create terrible waste and smell and was dangerous for the workers and the environment. It is also what gave tanners a very low status in society.

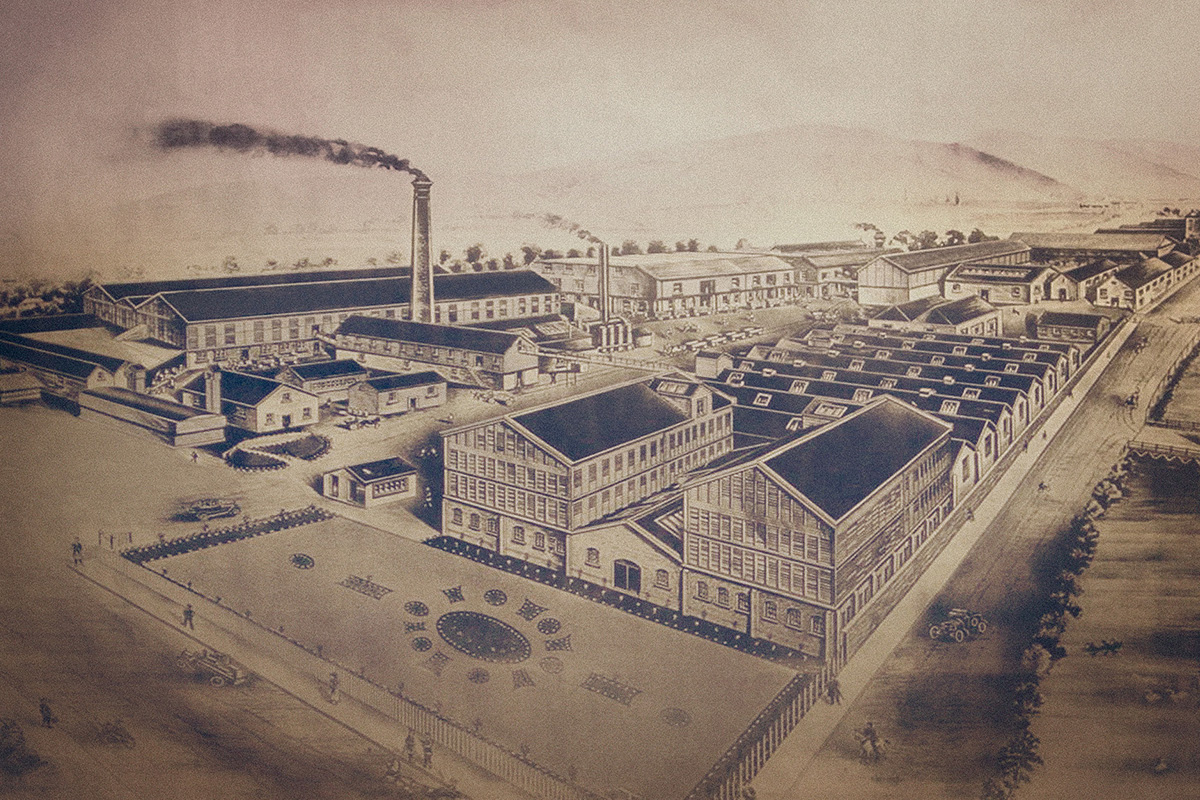

Modern tanning is a highly industrialized process that is quite clean or even “sterile”. It involves numerous chemicals, consumes large amounts of water and utilizes a variety of heavy machinery, but environmental legislation in industrial countries puts strict restrictions on environmental impact. Over the last decades, a lot of the tanning industry has moved to Asia. Where unfortunately, environmental legislation may not be as strict, or compliance with laws is not as good. Therefore, humans as well as the environment may suffer. In particular, the emission of chemicals in waste water into rivers may be a hazard for the environment and for people working with it.